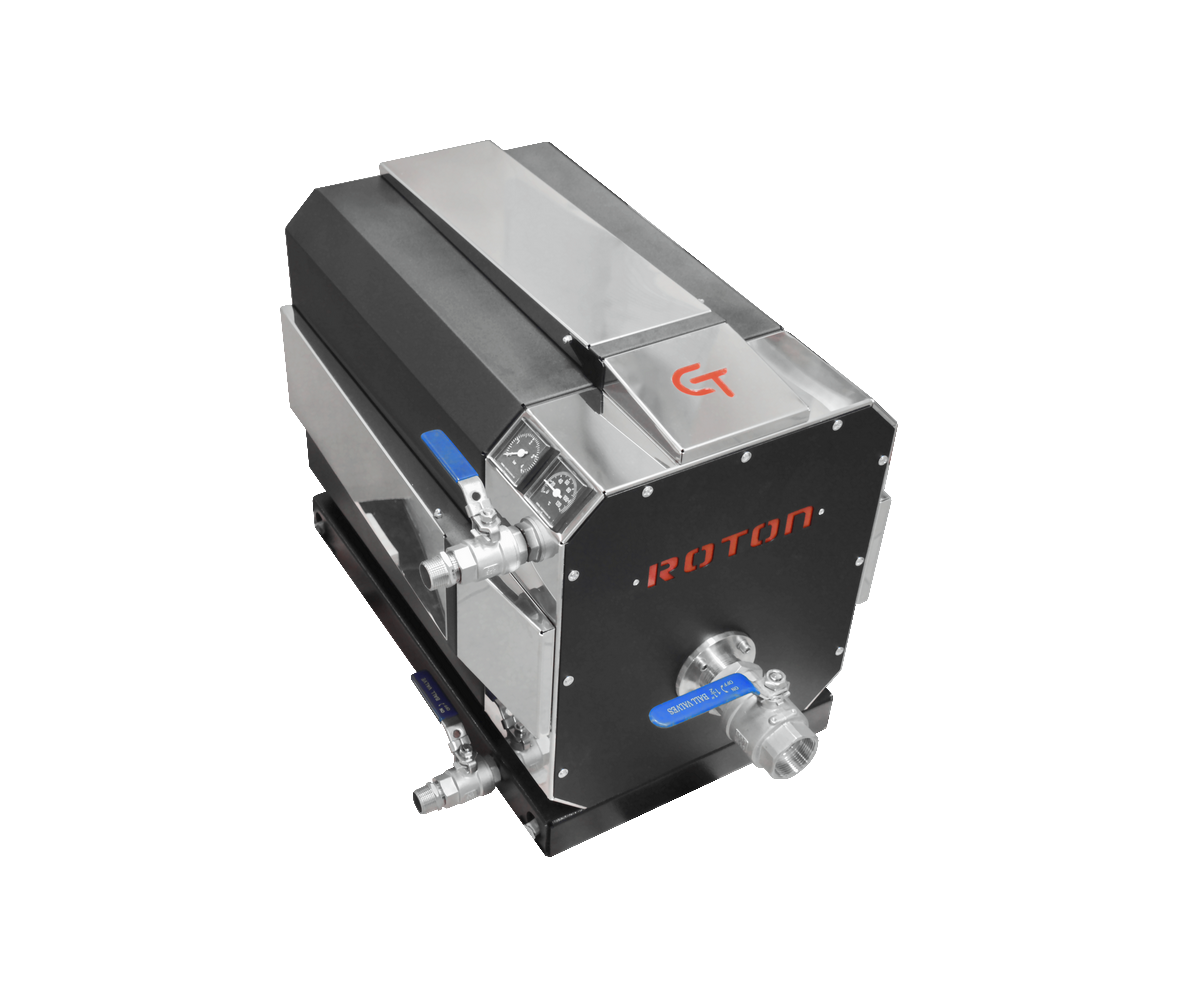

Roton

Pulsar-CT 930

Гомогенізація, пастеризація незбираного молока, а також відновлення сухого молока.

Збільшується стійкість обробленого незбираного молока при зберіганні в 3…7 разів (без упаковки), знижується температура пастеризації молока з 75…85°С до 60…65°С, а стерилізації з 150°С до 80…90°С без зміни його показників харчової цінності, водночас із пастеризацією молока відбуваються процеси гомогенізації.

При відновленні сухого незбираного молока повністю виключаються його втрати, значно підвищується якість відновленого молока, одночасно з відновленням проводиться його пастеризація та гомогенізація. У процесі гомогенізації досягається рівномірний розподіл жиру, однорідність продукту та його підвищена в’язкість. Продукт набуває стійкості до відстоювання вершків та розвитку процесів окислення.

Інтенсифікація технології отримання етанолу

На початковій стадії обробки зерна в процесі приготування замісу з використанням кавітаційного реактора відбувається значна зміна різних сухих речовин з одночасним накопиченням низькомолекулярних форм вуглеводів, що зброджуються і незброджуються, декстринів різної молекулярної маси, амінного азоту. Застосування кавітаційної обробки забезпечує глибоку деструкцію сировини, що сприяє більш легкому їх розчиненню при подальшій тепловій та ферментативній обробці. Використання кавітаційного реактора дозволяє переробляти помели з різним гранулометричним складом частинок зерна жита та отримувати середовища з високим вмістом розчинних сухих речовин без погіршення реологічних показників. Вміст високомолекулярних декстринів і редукуючих речовин збільшується вдвічі, розчинного білка втричі більше, ніж у замісі традиційними методами. Скорочується вихід барди на 50% та забезпечується повторне використання фільтрату барди у технологічному процесі на різних його стадіях. При роботі за новою технологією можливе використання м’якшого режиму обробки, що призвело до зменшення теплоенерговитрат на 25-30%. Ступінь гідролізу концентрованого осахаренного сусла за пропонованою технологією становить 95-97%.

Інтенсифікація вирощування товарних хлібопекарських дріжджів

Збільшення питомої швидкості зростання дріжджів та накопичення біомаси із застосуванням у технологічному процесі кавітаційного реактора пояснюється тим, що збільшується різниця в осмотичному тиску зовні та всередині клітини і, як наслідок, покращується засвоєння клітиною поживних речовин. Поліпшення процесів масообміну та масопереносу у дріжджовій суспензії підвищує відтік метаболітів з клітини, а отже сприяє розмноженню дріжджів. Нанопроцеси, які у кавітаторі, руйнують конгломерати дріжджів з вибудовуванням в окремі ланцюжки і навіть із появою одиночних клітин. Це сприяє збільшенню сумарної поверхні дріжджових клітин, що знаходяться в одиниці об’єму, що покращує поглинання кисню та поживних речовин. Удосконалення технологічного процесу вирощування товарних хлібопекарських дріжджів із застосуванням методу кавітаційної обробки дозволяє збільшити питому швидкість зростання та продуктивність накопичення біомаси на 25-35%. У зв’язку з цим на цю величину скорочується тривалість процесу.

Виробництво соків, пюре, однорідної консистенції із м’якоттю

При виробництві натуральних соків одне з основних завдань полягає в тому, щоб стабілізувати м’якуш у зваженому стані. З огляду на це основною операцією у виробництві соків з м’якоттю є тонке диспергування до розмірів частинок не більше 50 мкм. За рахунок зменшення розмірів часток м’якоті до 10-50 мкм збільшується стабільність тонкої дисперсії, знижується масова частка м’якоті за рахунок переходу нерозчинного протопектину у водорозчинний пектин, збільшується в’язкість соку від 6,8 до 12,2 сП, значно зменшується споживання енергії. Інші показники – масова частка сухих розчинних речовин і кислот, що титруються, залишаються практично без змін. Таким чином, використання кавітаційної обробки як гомогенізатор забезпечує отримання гомогенного, стабільного продукту, який практично не розшаровується при зберіганні. Частинки м’якоті мають дрібнодисперсну структуру, що зумовлює високі смакові якості.

Освітлювання вина тонко диспергованою суспензією бентоніту

Завдяки силам взаємодії між зарядами частинки бентоніту адсорбують домішки та переводять в осад частинки різних колоїдів вина з протилежним електричним зарядом. Внаслідок адсорбції та випадання в осад частки утворюють великі агрегати, які осідають у масі вина. При цьому відбувається освітлення і вміст різних екстрактивних нестабільних речовин зменшується.

На відміну від освітлюючих білкових речовин, що діють в асоціації з таніном, мінеральні речовини (бентоніт) утворюють колоїдні або зважені частинки (каолін), які завдяки наявності негативних електричних зарядів переводять в осад протилежно заряджені частинки. Кавітаційна технологія забезпечує диспергування бентоніту до розмірів частинок (0,1-2,0) мкм, зменшення його витрат при обробці виноматеріалів до 10 разів, збільшення продуктивності освітлення (до 5-8 разів) з покращенням якості кінцевого продукту.

Переробка відходів виноробства (шкірки та кісточок винограду)

Переробка відходів дозволяє отримати цінні продукти, необхідні для низки галузей народного господарства: етиловий спирт, винна кислота, виноградна олія, поліфенольні концентрати, слабоалкогольні та безалкогольні напої та інші продукти харчового, косметичного та фармацевтичного призначення.

Застосування магнітно-імпульсного кавітаційного реактора “ROTON” у пивоварному виробництві

Обробка заторів в реакторі підвищує ефективність виробництва пива за рахунок більшого вилучення екстрактивних речовин солоду, економії сировини, також покращує якість пивного сусла, позитивно впливає на процес бродіння та якість готового напою.

Обробка заторів в реакторі протягом 5 хвилин є достатньою для оцукрювання затору і накопичення необхідної кількості сухих речовин, що призводить до більш повного розщеплення білка, знижує екстракцію поліфенолів. Тривалість зброджування скорочується до 4 діб.

Спиртове екстрагування дубового натурального екстракту для виробництва коньячної продукції

Кавітаційна обробка спеціально підготовлених дубових трісок для виробництва коньяку дозволяє прискорити в десятки разів ступінь та глибину екстракції компонентів деревини дуба у коньячний спирт. Усе це зрештою призводить до отримання продукції з поліпшеними органолептичними якостями у стислі терміни.