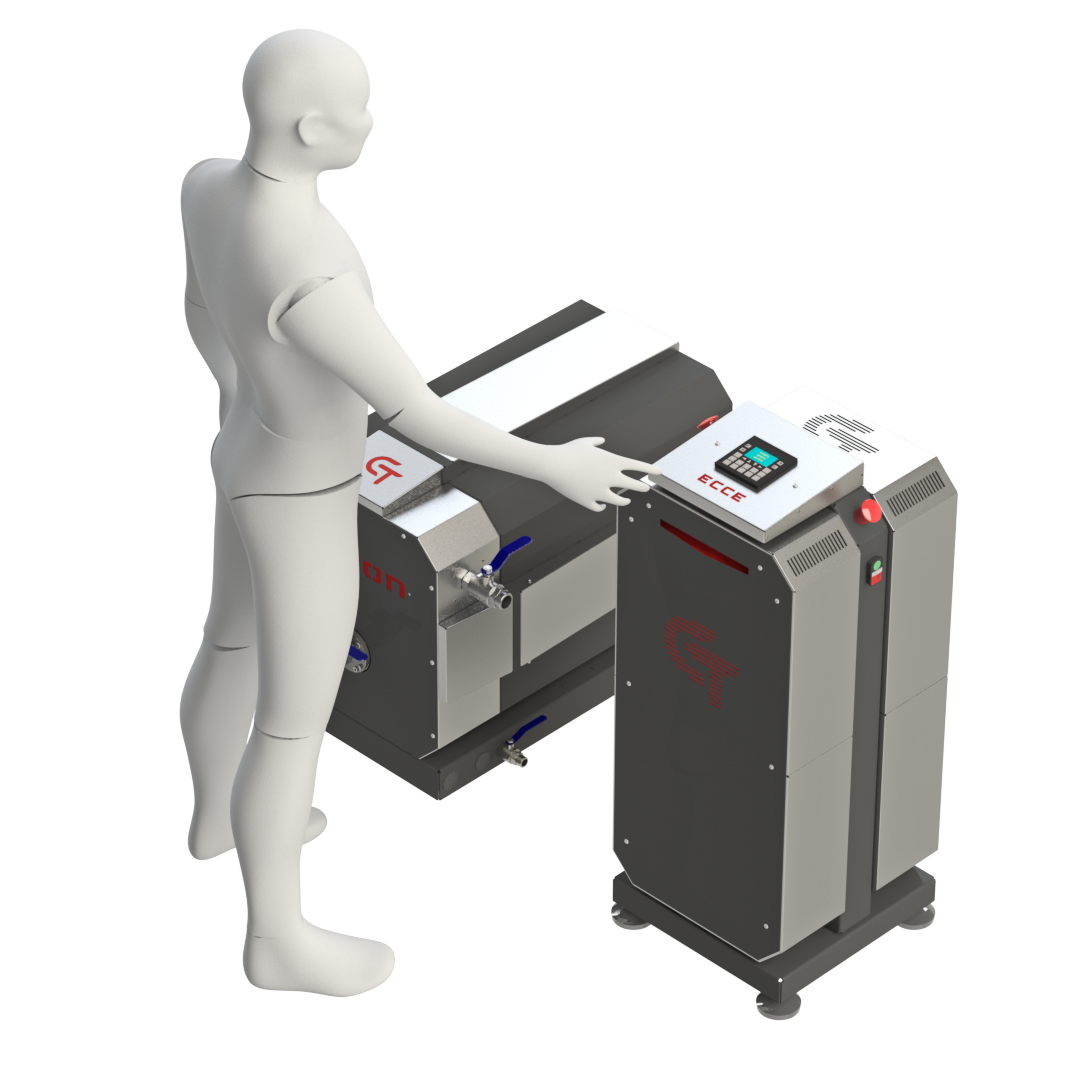

Магнітоімпульсні кавітаційні реактори “ROTON” показують високу ефективність при виробництві різних екстрактів із застосуванням харчових розчинників, таких як етиловий спирт, олія, вода.

За якістю гомогенізації, глибини екстракції, продуктивності та витрат енергії аналогів даних апаратів не існує.

Кавітаційний реактор “ROTON” може переробляти рідини з продуктивністю до 8000 літрів на годину в’язкістю до 1000 cSt і вище, будь-які поєднання різних рідин та рідини з твердими включеннями при мінімальному гідромодулі 4.

Екстрагування рослинної сировини в даний час здійснюється малоефективними, трудомісткими та тривалими методами.

Класичними методами виділення біологічно активних сполук з рослинної сировини є екстракція із застосуванням токсичних розчинників, при цьому завжди виникає проблема відокремлення від екстракту залишків розчинника, що може призвести до часткового або навіть повного руйнування деяких компонентів екстракту, а також до забруднення кінцевого продукту нехарчовими хімічними сполуками.

На сьогоднішній день найбільш популярним із існуючих методів екстракції є екстракція зрідженими газами. Це бутанова екстракція та екстракція зрідженим діоксидом вуглецю (СО2). Обидва ці методи мають ряд істотних недоліків:

Бутанова екстракція:

- Бутан – токсична речовина. Неможливо 100% видалення з екстракту.

- Невелика продуктивність через пакетну обробку (порціями).

- Часта зміна фільтрів.

- Великі енергетичні витрати та дорожнеча обладнання для повторного зрідження розчинника.

Екстракція діоксидом вуглецю:

- Надвисокий тиск (від десятків до сотень атмосфер).

- Висока вартість обладнання (компресори, судини під великий тиск) та великі енергетичні витрати.

- СО2 – неполярний розчинник. Вибіркова екстракція, часта втрата корисних компонентів.

Наша технологія не тільки позбавлена цих недоліків, а й має цілу низку істотних переваг:

- Висока продуктивність обробки сировини у потоці, на відміну традиційної пакетної обробки.

- Значно нижча собівартість екстрагування у порівнянні з традиційними методами, переліченими вище.

- Універсальність технологічного процесу. На тому самому обладнанні можлива екстракція різних типів сировини, без переналаштування технологічної лінії.

- Збільшення ступеня екстрагування у вигляді руйнування клітинних мембран. Кавітація механічно руйнує стінку клітини силами зсуву, полегшується перенесення маси з клітини в розчинник. Зменшення розміру частинок за допомогою кавітації збільшує площу поверхні контакту твердої та рідкої фаз.

- Використання нетоксичних полярних розчинників (спирти, вода та ефіри), як наслідок, можливість екстрагування складніших сполук.

- Безпека процесу екстрагування – немає високих тисків, відсутність токсичних розчинників.

- Етерифікація органічних кислот із виділенням ефірів у процесі екстракції, які легше засвоюються організмом людини.

- Отримання продукції тільки класу “ОРГАНІК” – в екстракції беруть участь лише 100% натуральних інгредієнтів.

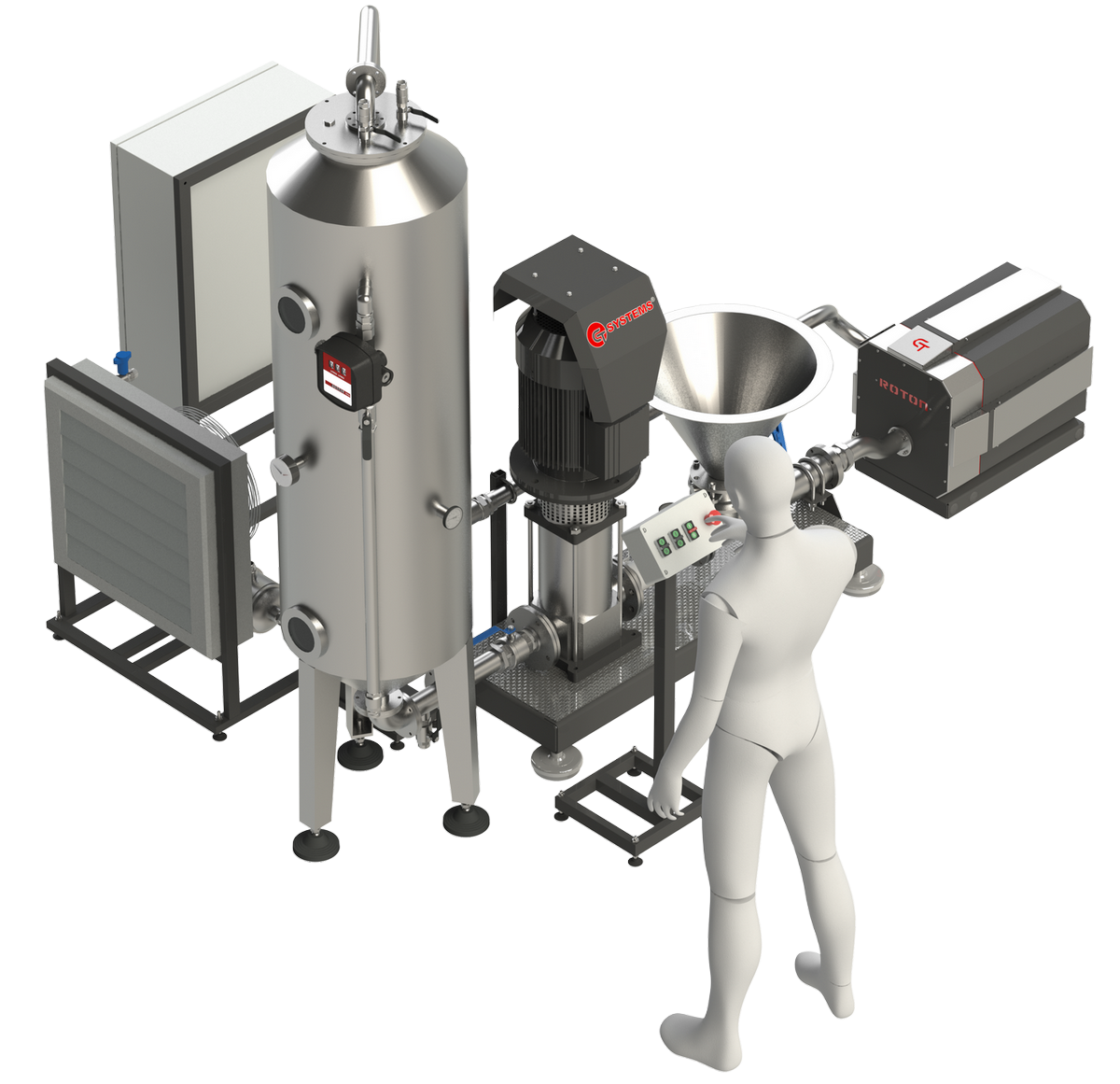

Приклади практичного використання магнітоімпульсних кавітаційних реакторів “ROTON” у деяких технологічних процесах

Екстракція етиловим спиртом крильової олії з крильового борошна

Одним із прикладів розв’язання задачі дуже складної екстракції є екстракція крильової олії. Крильова олія – дуже цінна і дорога харчова добавка. Вона на порядок ефективніша за риб’ячий жир. Діючими корисними речовинами крилової олії є Омега-3 жирні кислоти, фосфоліпіди та найсильніший природний антиоксидант – астаксантин. Всі ці три типи речовин мають різну розчинність у полярних та неполярних розчинниках. Традиційне екстрагування проводиться мінімум двома різними розчинниками у два етапи, причому один із цих розчинників – обов’язково нехарчовий. Тому всі зразки крильової олії, присутні на ринку, не можуть бути сертифіковані як продукт “органік”.

Наша компанія, використовуючи унікальний кавітаційний реактор “ROTON”, розробила та випробувала технологію проточної кавітаційної екстракції крильової олії харчовим етиловим спиртом. При цьому в одній стадії вдалося одночасно отримати жири, фосфоліпіди та астаксантин. Усі параметри екстракту відповідають ринковим нормам для крильової олії.

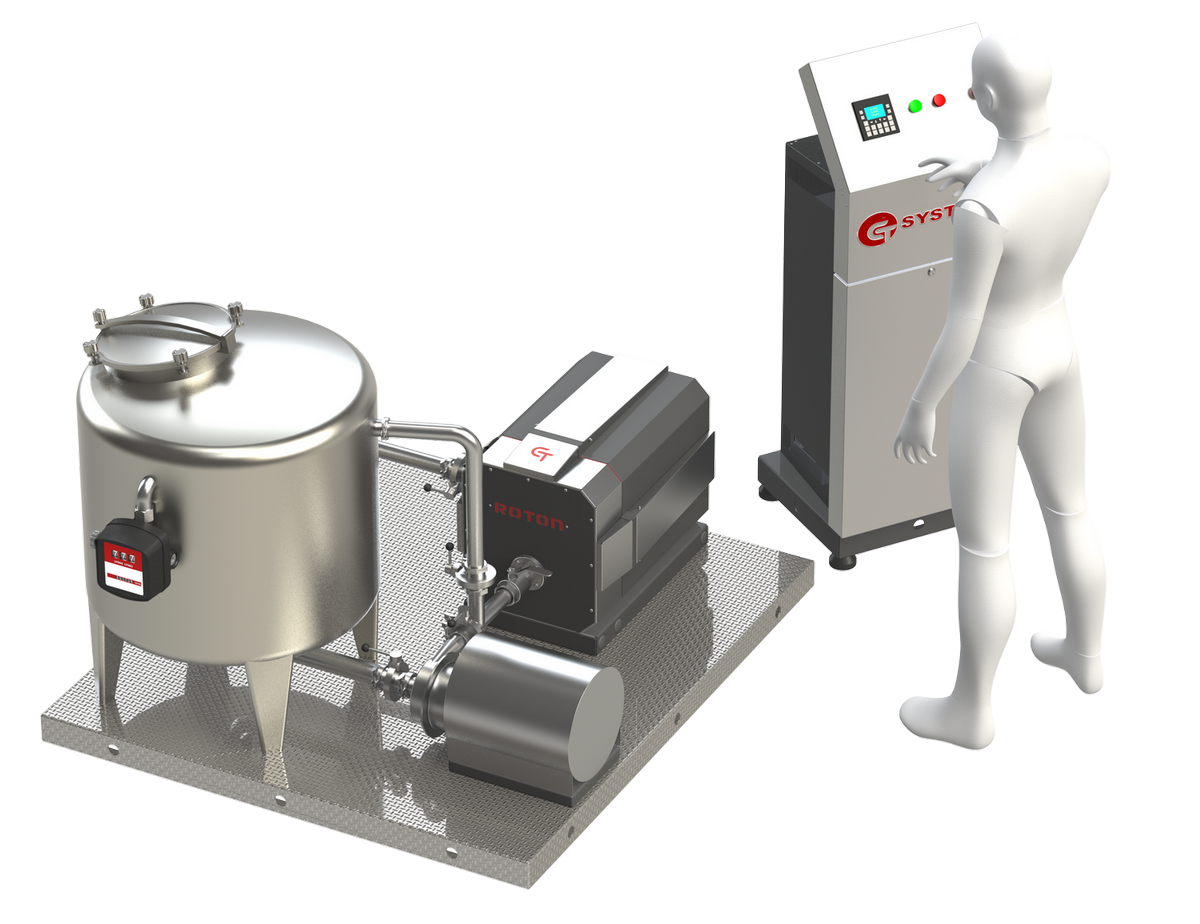

Одержання екстракту медичного каннабісу

Такий канабіс практично не містить наркотичних каннабіноїдів, зате містить помітну кількість каннабідіолу (CBD) – дуже корисної речовини, яка ефективно допомагає позбавлятися від стресу, безсоння, алкогольної чи наркотичної залежності та має ще цілу низку лікувальних ефектів.

Одержання екстракту канабісу на наших кавітаційних реакторах проводиться за допомогою харчового етилового спирту 95,5%, при цьому вилучається понад 95% каннабіноїдів.