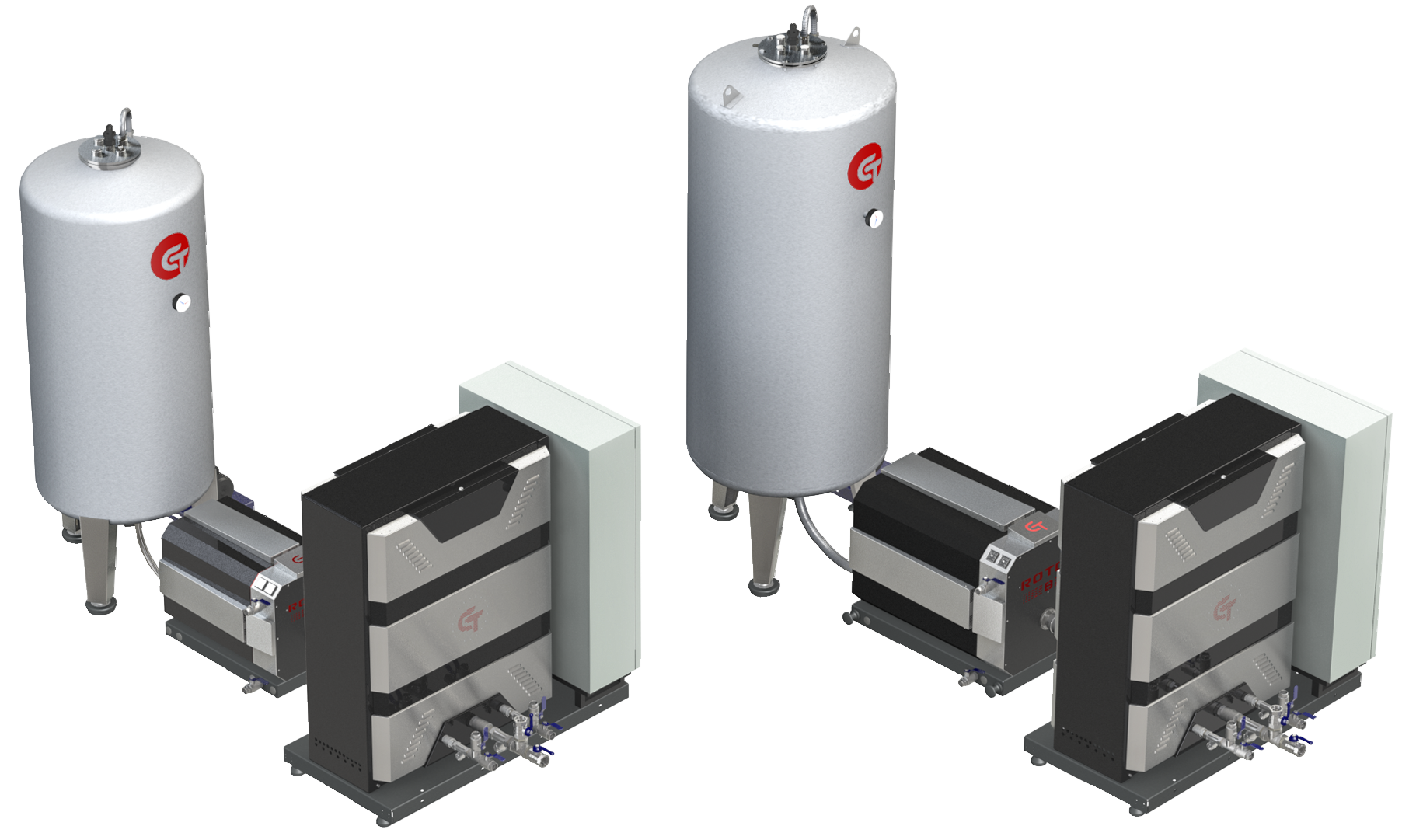

The automatic equipment for the production of biodiesel BIOTRON-R are the latest development of our company. These models are based on the well-known and proven automatic equipment BIOTRON-CT and ultra-efficient cavitation processors ROTON-B. In the design of BIOTRON-R units, our engineers considered the years-long experience of successful operation of previous models and introduced the recent, most effective technologies of our company. The new automatic equipment BIOTRON-R are characterized by the highest rate of fatty acid methyl esters conversion, up to 99%, low energy consumption, small dimensions, low noise level, high reliability and the unique software that significantly minimizes the human factor impact.

Technical parameters

|

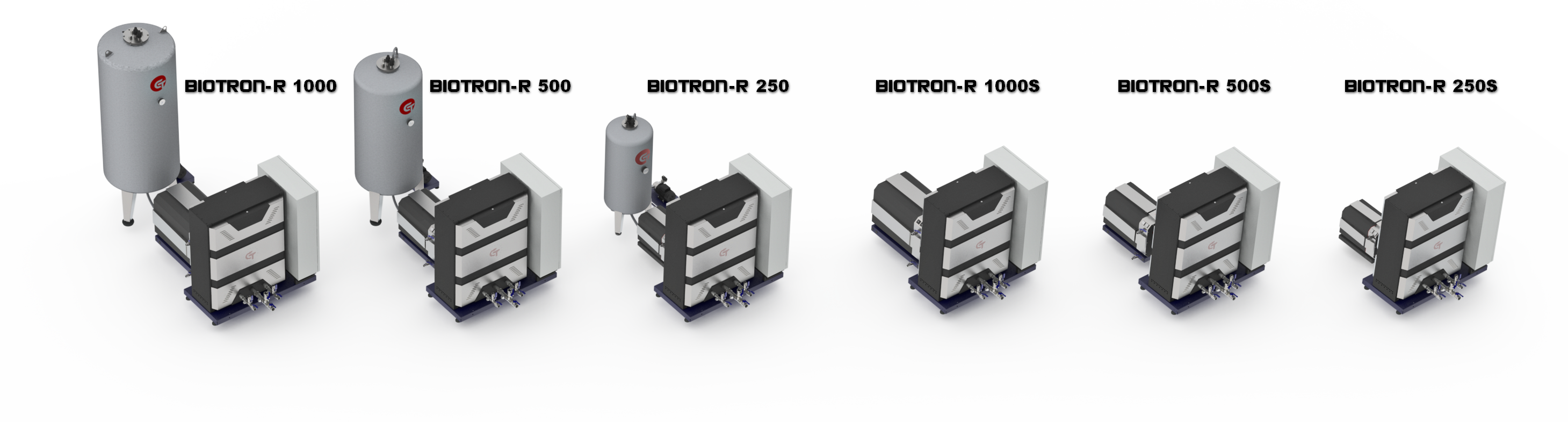

BIOTRON-R 250

|

BIOTRON-R 500

|

BIOTRON-R 1000

|

|

| Capacity (rated), liters per hour |

250-300

|

500-600

|

1000-1200

|

| Rated power, kW |

11

|

16

|

32

|

| Weight (approximately), kg |

580

|

765

|

975

|

| Maximum allowed liquid temperature in module, °C |

90

|

90

|

90

|

| Automation level |

ultimate

|

ultimate

|

ultimate

|

| Operation mode |

continuous

|

continuous

|

continuous

|

| Processing efficiency, kW hour/liter |

0.028

|

0.028

|

0.028

|

| Capacity adjustment |

yes

|

yes

|

yes

|

| Processed liquid special requirements |

no

|

no

|

no

|

| Floor space occupied with one module, sq.m. |

2.8

|

3.0

|

4.0

|

| Overall dimensions (L x W x H), mm |

1950х1380х1980

|

2300х1380х2230

|

2520х1380х2620

|

| Explosion proof certificates |

ATEX

|

ATEX

|

ATEX

|

|

BIOTRON-R 250-S

|

BIOTRON-R 500-S

|

BIOTRON-R 1000-S

|

|

| Capacity (rated), liters per hour |

250-300

|

500-600

|

1000-1200

|

| Rated power, kW |

10

|

17

|

32

|

| Weight (approximately), kg |

460

|

575

|

785

|

| Maximum allowed liquid temperature in module, °C |

90

|

90

|

90

|

| Automation level |

semi

|

semi

|

semi

|

| Operation mode |

continuous

|

continuous

|

continuous

|

| Processing efficiency, kW hour/liter |

0.028

|

0.028

|

0.028

|

| Capacity adjustment |

yes

|

yes

|

yes

|

| Processed liquid special requirements |

no

|

no

|

no

|

| Floor space occupied with one module, sq.m. |

2.0

|

2.0

|

3.0

|

| Overall dimensions (L x W x H), mm |

1440х1380х1411

|

1440х1380х1410

|

1500х1380х1410

|

| Explosion proof certificates |

ATEX

|

ATEX

|

ATEX

|

AUTOMATIC MODULES BIOTRON-R CONSIST OF THREE MAIN UNITS:

1. ROTON-B magnetic impulse cavitation processors

The reactor ROTON-B is the core element of the automatic equipment BIOTRON-R. It is the result of the latest developments of our company in the field of physico-chemical mechanics and sonochemistry.

Cavitation in the processors ROTON-B is created by the magnetic impulse hydrodynamic method. Currently, it is the most effective method to create cavitation directly in the fluid stream, patented by our company. The cavitation cloud is held by a magnetic field exactly in the processing area of the reactor and has an immediate effect on the feedstock passing through the cavitator. Therefore the high efficiency, reliability and durability of our units is ensured. The processors ROTON-B do not require high quality feedstock and currently have the highest efficiency among biodiesel production equipment.

Technical parameters

|

ROTON-B7

|

ROTON-B15

|

ROTON-B30

|

|

| Capacity (rated), liters per hour |

250

|

500

|

1000

|

| Rated power, kW |

7,5

|

15

|

30

|

| Weight, kg |

130

|

235

|

420

|

| Operation mode |

continuous

|

continuous

|

continuous

|

| Processing efficiency, kW hour/liter |

0.028

|

0.028

|

0.028

|

| Flow rate adjustment |

yes

|

yes

|

yes

|

| Overall dimensions (L x W x H), mm |

700х450х500

|

960х560х600

|

1100х630х700

|

2. PPS-CT 1200 : ELECTRONIC SYSTEM FOR THE PRELIMINARY DOSING AND PROCESSING OF SOURCE PRODUCTS

Technical parameters

|

PPS-CT 1200

|

|

| Capacity (rated), liters per hour |

1200

|

| Number of components mixed |

3

|

| Rated power, kW |

2

|

| Explosion proof certificates |

ATEX

|

| Automation level |

Fully automatic

|

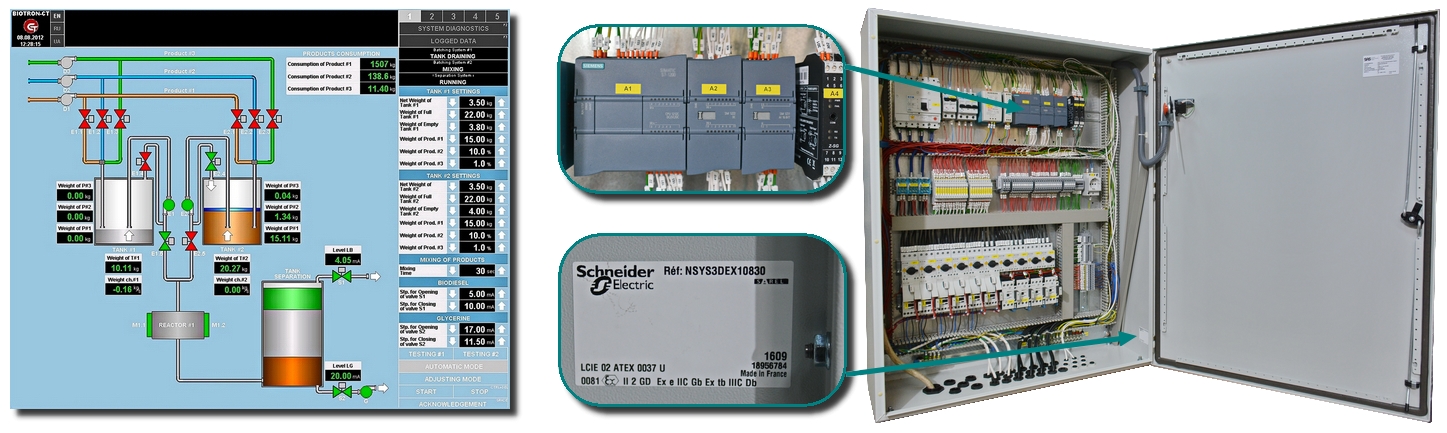

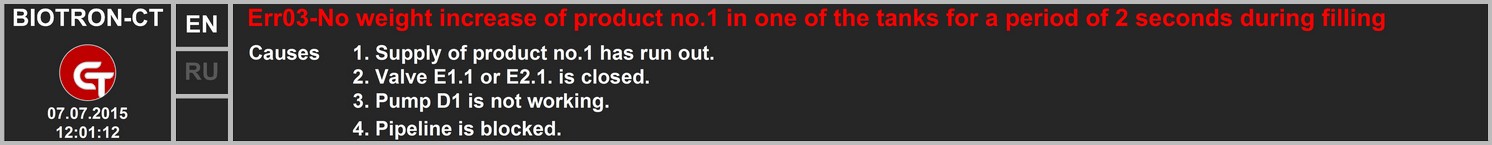

Modern dosing systems, used by other companies are not able to guarantee the steady dosing of source ingredients if ambient conditions (temperature, liquid level in source ingredients and prepared products tanks, oil viscosity, etc.) change. The system which our company has designed does not include these disadvantages and has an extremely high dosing precision – 0.1%. In addition, the system is equipped with a pre-mixing unit, there is the option of adjusting flow rate and pressure at the system output and there is also a source components dosing feature. The equipment uses original software and high-reliability electronics produced by the company FANUC. The PPS-CT 1200 system also includes a biodiesel fuel production safety tracking function. The processor tracks the source component availability, their filling speed, mixing intensity, ability to pass through pipelines and valves, etc. If there is an emergency, the processor will stop the whole system; send an audible signal to operator and show the error code on the display, together with a detailed description and possible causes. In this way, for example, if there is an oil shortage in the source products storage, the following message will be displayed:

The operator should identify the exact cause of the system stop and eliminate it. The system also features test reaction procedures i.e. test processing of small volumes (up to 10 liters) of source components. This feature may be useful for new oil or animal fat changeover.

3. ELECTRONIC TRACKING SYSTEM OF THE FILLING, SEPARATION AND DISCHARGE OF FINISHED PRODUCTS

Our automatic unit contains the separation process tracking system in order to eliminate the human factor in biodiesel availability evaluation (“by-sight”). The supersensitive sensors monitor the state of the glycerol and biodiesel in the separation tank. Data obtained by the sensors is transferred to the computer, which evaluates the readiness of the source products and also controls biodiesel and glycerin discharge from the separation tanks to the finished product storage. The entire process takes place in continuous mode. If any unforeseen situation occurs, and, for any reason, the separation does not take place or takes place at a poor speed, the computer will stop the entire system and send a signal to the operator about the need to analyze and correct the situation. For more information about the operation of the separation process tracking system please see the animated presentation.

USER-FRIENDLY INTERFACE SOFTWARE, WHICH DOES NOT REQUIRE THE OPERATOR TO HAVE SPECIAL SKILLS

All processes which take place in the automatic module are controlled by the microprocessor. The interface that our software team has developed is very simple and self-explanatory. The operator is able to control the whole system just by clicking a mouse button. In the adjustment mode, the operator can control any module mechanism separately, set the necessary sensor response value, etc. In the automatic mode, just click the START button – the BIOTRON-CT system will do the rest itself. One computer can serve up to five BIOTRON-CT automatic equipment at once. Software and electronic components are designed based on the software and electronic components produced by the Japanese company FANUC or SIEMENS – world market leaders in this area.